THE CRUCIAL ROLE OF ACOUSTIC ENCLOSURES

FUNDAMENTALS OF ACOUSTIC INSULATION: ATTENUATORS IN INDUSTRIAL ENVIRONMENTS

Noise control in industrial environments represents a challenge both for occupational safety and for compliance with various regulations. The objective of acoustic attenuation is to reduce the noise level caused by equipment and machinery in the processes carried out in industrial plants and facilities, minimizing the impact on the environment and providing safety and comfort.

Below, we discuss the basics of acoustic insulation, explaining essential concepts and measurement methods applicable to industrial systems.

WHAT IS AN ACOUSTIC ATTENUATOR? APPLICATIONS, FEATURES AND PHYSICAL LIMITS

An acoustic attenuator is a device designed to reduce the noise produced by the flow of air or gases in industrial, ventilation, or combustion systems. Its main objective is to alter the conditions of sound propagation, either by blocking, absorbing, or dissipating its energy.

PASIVE ACOUSTIC ATTENUATORS

Not all attenuator designs will respond in the same way in different environments. Industrial noise is variable, so it is necessary to analyze its origin, frequency, intensity, and form of propagation, as each device will use a different physical principle to reduce sound, adapting to specific needs.

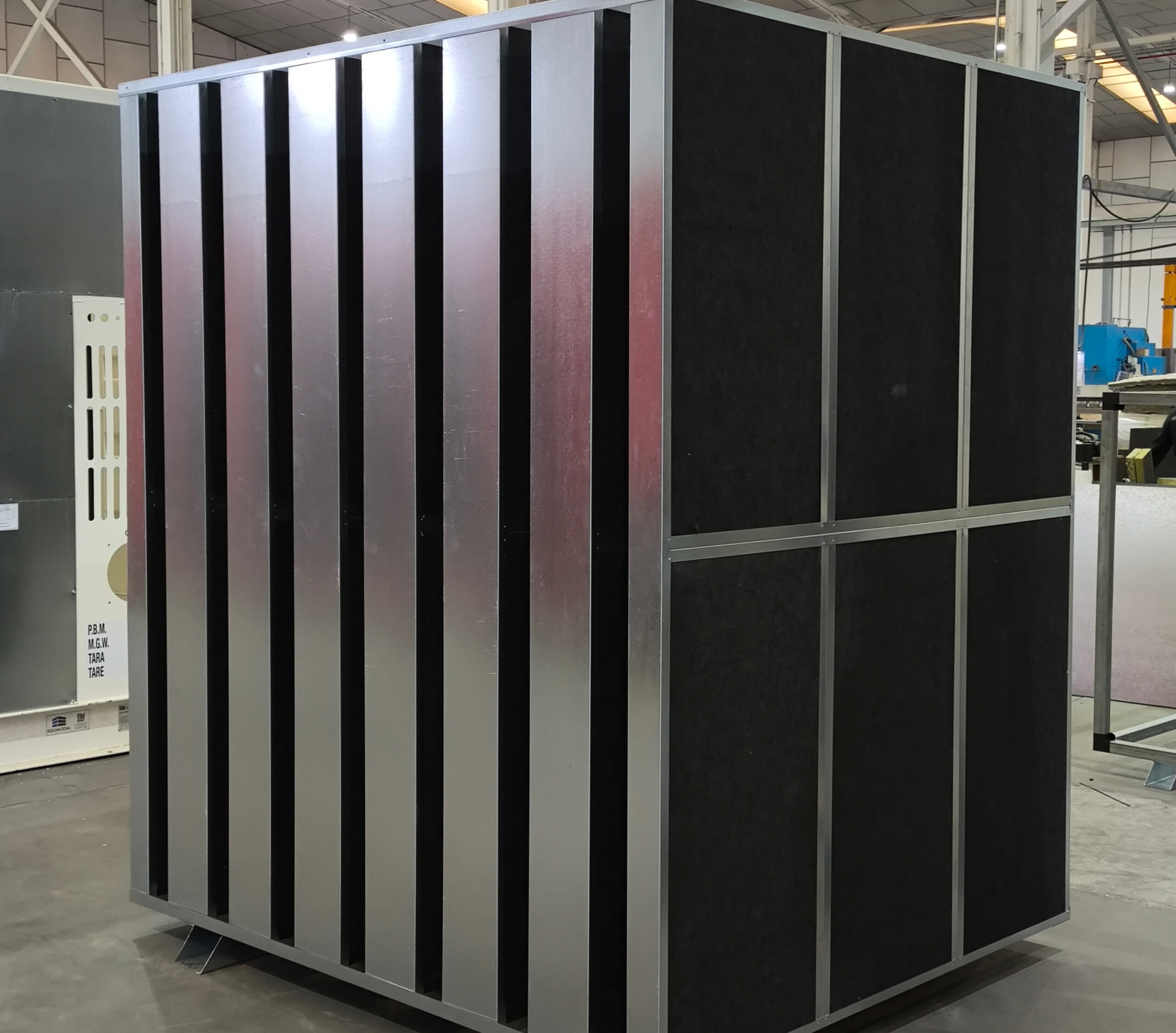

- Design and features of passive attenuators: Designed to attenuate noise generated in rooms with air intake and exhaust requirements, ventilation ducts, air conditioning and heating. This attenuator consists of an outer body made of galvanised sheet steel, which provides high resistance to deterioration for outdoor installations or in corrosive environments. Inside, these units are manufactured with custom-made baffles, according to the needs of the project, with an outer body made of galvanised steel and filled with rock wool of different densities to achieve optimal absorption of sound waves. These baffles also have a protective veil that offers greater durability and prevents internal degradation of the material, in this case rock wool.

APPLICATIONS

Ventilation and air conditioning systems (HVAC)

In heating, ventilation and air conditioning systems, the movement of air through ducts generates noise that can be annoying. For this reason, attenuators are often installed in ducts, air intakes and outlets, and central units, all without compromising air flow.

Air intake and exhaust in internal combustion engines

In this case, attenuatorsare used to reduce the noise emitted to the outside by combustion engines, both diesel and gasoline, which produce noise due to the explosion of fuel and the flow of exhaust gases. In this way, low and medium frequencies are controlled, resulting in improved working conditions and protection of the environment.

Industrial processes with turbines or compressors

The noise generated by constant flows of air or gases in high-powered rotating equipment can be significant. In this regard, attenuators reduce high-speed and high-pressure sound, maintain flow efficiency without generating excessive pressure losses, and adapt to different frequency ranges depending on the type of equipment and the characteristics of the process.

Power generation plants

In thermal, hydroelectric, or wind power plants, attenuators play a key role, as they contribute to increasing the occupational safety of workers who are exposed to a considerable reduction in previously high noise levels. These types of facilities also comply with environmental noise regulations, which aim to protect nearby communities without affecting equipment performance.

Anechoic chambers or test laboratories

Sectors such as aeronautics, telecommunications, automotive, quality control, and acoustic product research and development, among others, require controlled environments where noise is minimal. In these areas, attenuators allow precise acoustic conditions to be maintained for the development of acoustic tests or prototypes with accuracy, ensuring that measuring instruments are not affected by external interference.

PHYSICAL LIMITS

Attenuators have their own limitations, as their maximum attenuation depends on geometry and frequency range, dissipative devices are less effective below 125 Hz, size and pressure drop affect design feasibility, and there is always a trade-off between acoustic reduction and energy efficiency.

HOW TO MEASURE THE ACOUSTIC EFFECTIVENESS OF A SYSTEM

The characterization and validation of acoustic attenuation systems requires standardized metrics.

DECIBELS

Sound pressure level is measured in decibels (dB), a logarithmic scale that reflects the relative intensity of sound relative to a reference (20 µPa in air). A reduction of 10 dB is perceived as approximately half the volume.

OCTAVE BANDS

To analyze acoustic efficiency, the spectrum is broken down into octave or third-octave bands, which allows us to identify how the system responds at different frequency ranges. This resolution is essential for designing attenuatorsadapted to the actual noise spectrum.

ACOUSTIC PERFORMANCE INDICES

- IL (Insertion Loss): difference in dB between the sound level measured before and after installing the attenuator under operating conditions.

- TL (Transmission Loss): intrinsic capacity of the attenuator to attenuate sound, measured under controlled conditions.

- NR (Noise Reduction): reduction in the sound level perceived at a specific point, taking environmental factors into account.

STANDARDS AND TEST METHODS

The effectiveness of an attenuator must be validated in accordance with international standards, such as:

- ISO 7235: measurement of transmission loss and insertion loss of attenuators.

- ISO 3744 / ISO 3746: determination of sound power levels.

- ASTM E477: standards for testing silencers in air systems.

- ISO 129-1: standard applied at HiAcoustic for the technical representation of our designs, guaranteeing accuracy and uniformity in the technical documentation provided to the customer.

- EN 1092-1 Type 1 PN 6 or, alternatively, DIN 2573: standards used for the manufacture of flanges and gaskets for exhaust silencers, ensuring compatibility, safety, and dimensional compliance.

CONCLUSION

Acoustic attenuation in industrial environments requires a balance between design, materials, and measurement. Attenuators in their various options are a fundamental tool for controlling noise, but they must be selected considering the operating conditions and current regulations. A comprehensive approach such as the one we offer at HiAcoustic, combining mechanical, reactive, and dissipative attenuation, backed by accurate measurements in decibels and octave bands, guarantees the success of the industrial acoustic strategy.